Sample GPR Scans & Reports

Ground penetrating radar offers an incredibly detailed look below the surface before any concrete cutting, coring, drilling, or other construction work is undertaken. When you work with Concrete Visions, we use the latest technology to create 3D scans of your area and compile those scans into a detailed report. We’ll provide visual documentation of the location of various obstructions or voids, helping you avoid any difficulties before you begin cutting.

Concrete Visions scans are 3D and Real-Time

Our GPR scans are compiled from a series of cross-sections, or line scans, which offer a much more accurate representation of the area. 2D imaging, or line scanning, is a single cross section of the area. While we do offer 2D line scanning as a more affordable option, it is not the most effective way to determine the location of obstructions within the concrete. For example, if a 2D line scan is performed, any rebar or conduit running diagonal to the plane of the scan may not be picked up in the results.

Our GPR scans are also performed in real-time, which means, a supervisor at our headquarters is able to view the scan results with the technician that is on site. We can evaluate the results and point out any potential concerns or areas to avoid. This is a big part of why our concrete scanning services have an accuracy rate of over 99%.

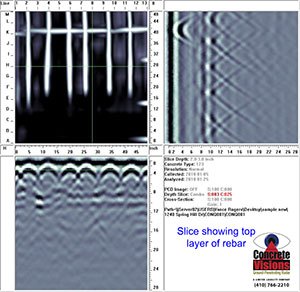

Sample GPR Scan

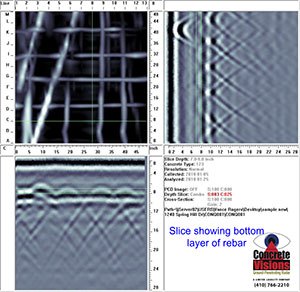

In the slice shown in the scan to the left, you can see the location of rebar within the concrete. GPR is highly effective at locating rebar and other metallic obstructions. The image in the top left shows the location of rebar in a cross section, looking down onto the surface. At right and bottom, you can see two different side view cross section of the concrete. The report also provides detailed information on the depth of the slice shown. In this instance, the slice shows a depth of 2 to 3 inches.

In the slice shown in the scan to the left, you can see the location of rebar within the concrete. GPR is highly effective at locating rebar and other metallic obstructions. The image in the top left shows the location of rebar in a cross section, looking down onto the surface. At right and bottom, you can see two different side view cross section of the concrete. The report also provides detailed information on the depth of the slice shown. In this instance, the slice shows a depth of 2 to 3 inches.

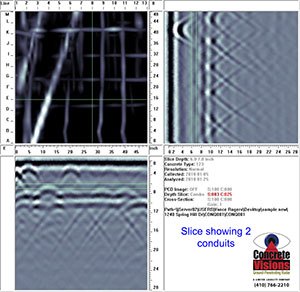

Conduits are shown in this slice, which was performed at a depth of 6 to 7 inches. GPR can be used to locate conduits, interior structural reinforcements, corrugated metal decking, radiant heat tubes, and steel mesh.

Conduits are shown in this slice, which was performed at a depth of 6 to 7 inches. GPR can be used to locate conduits, interior structural reinforcements, corrugated metal decking, radiant heat tubes, and steel mesh.

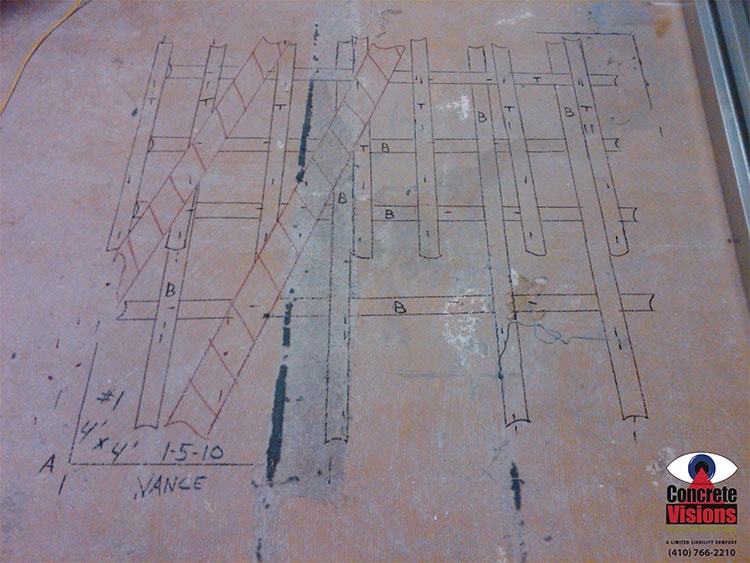

When the scan is complete, our technicians will map out the location of all obstructions and voids on the cutting surface. By presenting the data from our scans in this easy-to-follow visual map, we’re able to ensure an accurate cut and save our clients from any potential pitfalls.

When the scan is complete, our technicians will map out the location of all obstructions and voids on the cutting surface. By presenting the data from our scans in this easy-to-follow visual map, we’re able to ensure an accurate cut and save our clients from any potential pitfalls.