When breaking old concrete structures apart, it’s important to know the safest and most efficient means of doing it. Your workers will have to be trained on all of the best demolishing practices in order to be as quick, efficient, and safe as possible. Here is how you can break concrete up as efficiently and safely as you can.

The Tools You Will Need

Everyone is going to be required to have the right tools for the job. Such tools your workers will need include bolt cutters, pry bars, sledgehammers, mattocks, shovels, hand trucks, and wheelbarrows. The more tools that your workers are able to use, the better your situation will be. More tools means the concrete breaking process will be that much simpler.

On top of having the right tools for demolishing, you’ll also need the right protective gear. Personal protective equipment, also known as PPE, is a necessity, and you can also benefit from having drop cloths and plastic sheeting available.

Demolishing Concrete While Using PPE

Ensure that all of your personal protective equipment is working as it should. You’ll need goggles or glasses to protect your eyes. Arm protectors can shield your arms from danger. Vests are used to keep your torso safe while you work. There are also helmets for head protection, as well as face masks used to guard your eyes, mouth, and nose. Wearing the right steel-toed boots is advised as well. Lastly, breaking up concrete can get noisy, so wearing hearing protection is advised.

Breaking Your Concrete Slabs Up

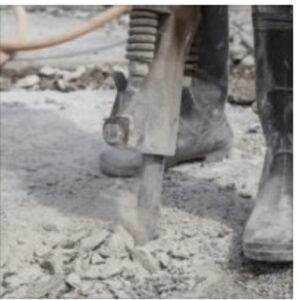

How you break concrete up will depend on the size of the slab. Wire cutting, dry ice blasting, or wire sawing could be effective breaking methods if you’re dealing with larger chunks. If you have a smaller piece of concrete that needs to be broken, it might be easier to go with a sledgehammer. More massive slabs could require the use of a jackhammer. If the concrete is reinforced, it will be more difficult to break. Regardless of the concrete slab’s size, remember to give yourself enough rest during the process. Even the most skilled professionals have to be sure they don’t push themselves too much at one time.

Concrete Visions Will Get The Job Done Right

Concrete Visions has been working with clients for over 25 years. Our G&M Services installers are certified with the industry’s major firestop product manufacturers. As part of our firestop service, we can assess abnormal field conditions and, with the manufacturer’s technical support assistance, provide engineering judgments in a timely fashion to comply with contract specifications. Our Field Mechanics undergo ongoing training, including mandatory monthly safety meetings, weekly Toolbox Talks where safety and equipment information is shred, and trainings on safe work standards and safety best practices.